About Us

Contact

Products

First Class Quality

We have a traditional commitment to quality. We strive to achieve excellence in our products, service and delivery. Throughout the years, we have won the confidence of popular brand names such as Gymboree, Gap, Pottery Barn and Next.

| Process | Description |

|

The first step to produce high quality garments is to have correct patterns. At Asia Thai Product, we use "Gerber Accumark System" to streamline our pattern, grading and marker making processes. |

|

Fabric shading and defect are major problems for garment production. At Asia Thai Product, we carefully check every yard of fabric with cloth inspection machine. |

|

Our cutting staff is operating a bandknife machine. |

|

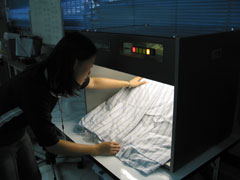

Our quality control staff employs light box to check fabric shading. |

|

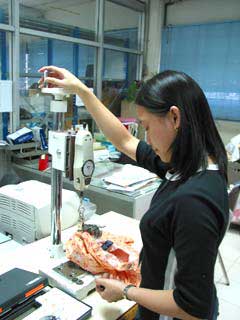

Since majority of our products are for babies and kids, we put extra care in testing strength of snaps, buttons and other accessories on garments. Routinely, we sample garments from production line to do the pull strength test to ensure that our products meet pull strength requirements. - Quality control staff uses "SafQ Strength Testing Equipment" to determine the physical safety and reliability of snaps, buttons and other accessories on garments. |

|

With the implementation of bar-code tracking production system, we are able to know in real time the progression of our production processes. This enables us to speed up production and solve bottleneck problems. Thus, we can gaurantee on time product delivery to our customers. |

|

Productivity is our key competitive advantage. Our workers are equipped with modern industrial sewing machines such brands as JUKI, BROTHER, PEGASUS, etc. |

|

Needle control procedures are implemented stringently in our factory. When the sewing operator breaks a needle, every effort is made to locate all of the needle fragments. The sewing operator has to report to authorized plant personnel with all needle fragments to get replacement needle. If all needle fragments cannot be found, the components or garments being sewn, including surrounding components/garments, will be taken to a separate area for thorough examination. If all the needle fragments still cannot be found, the component or garment being sewn will be destroyed. - Needle breakage control staff is recording needle breakage incidents in the Broken Needle Log. (top picture) - Needle breakage control staff is using 'Nissin' needle detector device to search for needle fragments on garment. (middle picture) - All finished garments must pass needle detector machine before they are passed to packing room. (bottom picture) |

|

With the implementation of Electronic Data Interchange (EDI) package called "REDI-to-Wear™", we are able to increase the efficiency and timeliness of communication with our customers. - Using "REDI-to-Wear™" program, our staff is printing bar-code labels to place on cartons before ex-factory. |